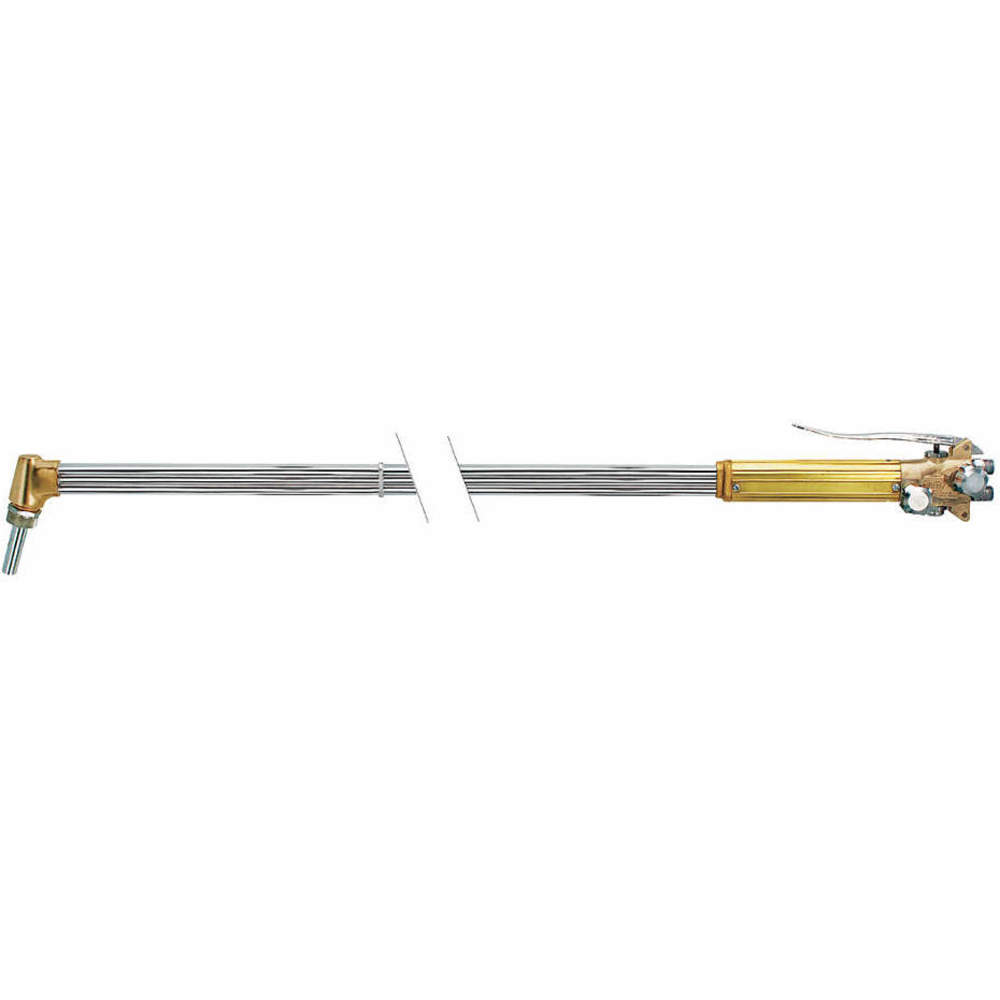

Cutting Torch

Miller-Smithcutting torches are ideal for heating & cutting metal workpieces using oxygen and any fuel gas like acetylene, propane, propylene & natural gas. They have two connections for attaching to gas supply lines from gas cylinders. Miller-Smith cutting torches have 75, 90 & 180 degrees head angles to fit cutting tips for cutting workpieces up to 24 inches at diverse angles from the user. They are equipped with gas knobs for controlling the oxygen to fuel gas ratio of the generated flame and a cutting oxygen lever for supplying high-pressure oxygen to melt & blow away the molten metal. These Miller-Smith cutting torches only need fitting of gas lines / hoses and cutting tips for fully assembling. Users need to hand tighten the cutting tip at the Miller-Smith cutting torch head after wrench tightening them. Miller Smith cutting torches have a sturdy body with an in tip mixture to mix & burn oxygen & fuel gas separately. The cutting tip seat is made of Graf-Tite to maintain positive seating & withstand extremely high temperatures.

Choose from a wide range of these Miller-Smith cutting torches, available in lengths ranging from 36 to 60 inches on Raptor Supplies. We also offer Miller-Smith cutting torch kitshaving torch handles that can fit cutting attachments, heating nozzles & welding nozzles for performing diverse cutting, welding & heating operations.

Uses

Miller Smith cutting torches are used to cut workpieces made of metal or metal alloys for fabrication, construction, maintenance, demolition, salvaging and shipyard applications.

Frequently Asked Questions

What size fuel gas tank should users select to efficiently run the cutting operation?

Size of a gas tank for use by Miller-Smith cutting torches is determined by the fuel gas used and its consumption along with oxygen gas. Generally, acetylene cylinder capacity per hour is seven times that of tip requirement. Alternate fuel (LP) gas cylinder capacity depends on the temperature but normally have greater gas volumes than acetylene cylinders.

Can natural gas delivered through utility pipes be used by Miller-Smith cutting torches?

Yes, natural gas delivered through utility pipes can be used by Miller-Smith cutting torches. However, this fuel gas supply is generally not pressurised enough to efficiently cut workpieces. Users may need a separate fuel gas manifold line to force the gas at enough pressure to reach the tip & generate a flame at a distance away from Miller-Smith cutting torch tips.

How to select the right fuel gas type for use in Miller Smith cutting torches?

Selecting a fuel gas for Miller-Smith cutting torches depends on several parameters like application requirements, workpiece thickness, material properties and the cost / availability of the fuel gas. Users should test each fuel gas over a set period to compare the work efficiency and overall cost of the gases used. Miller-Smith cutting torches generally are compatible with all fuel gases and only require compatible cutting tips for operation.

How to avoid overheating of Miller-Smith cutting torches?

Two main reasons for a Miller-Smith cutting torch & its tip to overheat are incorrect flame adjustments and insufficient gas supply to the torch. Generated flame lacks the velocity required to burn away from the cutting tip if enough gas is not supplied to Miller-Smith cutting torch. The resulting flame may recede into the torch & cause overheating. Users should use high-flow flashback arrestors with large cutting tips for less gas flow resistance & reduced overheating. They should also provide an appropriate amount of oxygen to prevent overheating as oxygen has a cooling effect on Miller-Smith cutting torch & its cutting tip.

What grade of the hose is suitable for use with Miller-Smith cutting torches?

Users should use "R" grade hoses with Miller-Smith cutting torches when the fuel gas used is acetylene and "T" grade hoses when they are using alternate fuel (LP) gases, such as propane, propylene and natural gas.

Change Country

Change Country