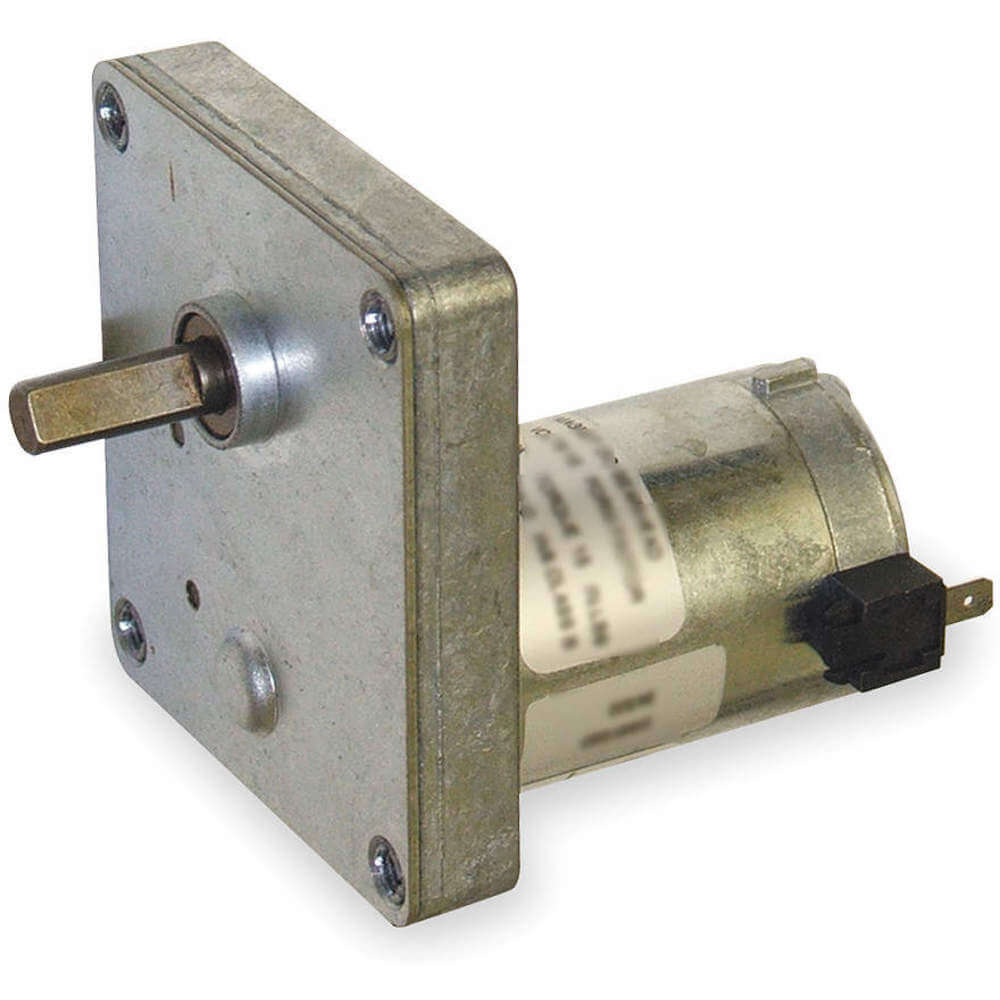

Dayton 1LPV4 DC gearmotor provides controlled rotational motion with precise speed and torque adjustments for reliable power transmission, contributing to the smooth operation of conveyor systems, robotics, automated devices and other mechanical applications.

Working Mechanism:

- DC gearmotor is affixed to a DC power source. Once energised, an electric current flows through the motor's coil, generating a magnetic field.

- Within the motor resides an armature (rotating component) along with a commutator. The commutator, a split ring connected to the armature, reverses the current's flow direction within the armature windings.

- The magnetic field, resulting from the armature's current, interacts with stationary magnets or field coils in the motor, initiating the armature's rotation and setting mechanical movement in motion.

- Equipped with an array of gears connected to the armature shaft, the gearmotor reduces the armature's swift rotation to a more controlled, slower speed. Simultaneously, this action augments the torque production.

- The gear motor's eventual output shaft is linked to the load or system requiring movement. As the armature turns, this motion is transferred via the gear reduction system to the output shaft.

Frequently Asked Questions:

Q. How often does Dayton 1LPV4 DC gearmotor require maintenance?

A. Maintaining the gearmotor on a routine basis is vital for achieving peak performance. Follow the manufacturer's guidelines to lubricate gears and bearings at regular intervals, which helps mitigate wear and promotes seamless operation.

Q. What factors should I consider when selecting a Dayton gearmotor for my application?

A. Take into account the torque demands, load attributes, speed requirements, voltage compatibility and environmental surroundings. Choose a gearmotor that aligns with the precise specifications of your application.

Q. Can I control the speed of this Dayton permanent magnet DC gearmotor?

A. Yes, it is possible to modify the speed of the gearmotor by regulating the voltage supplied to it. Decreasing the voltage generally leads to a slower rotational speed, while increasing the voltage tends to yield a swifter rotation.

Change Country

Change Country