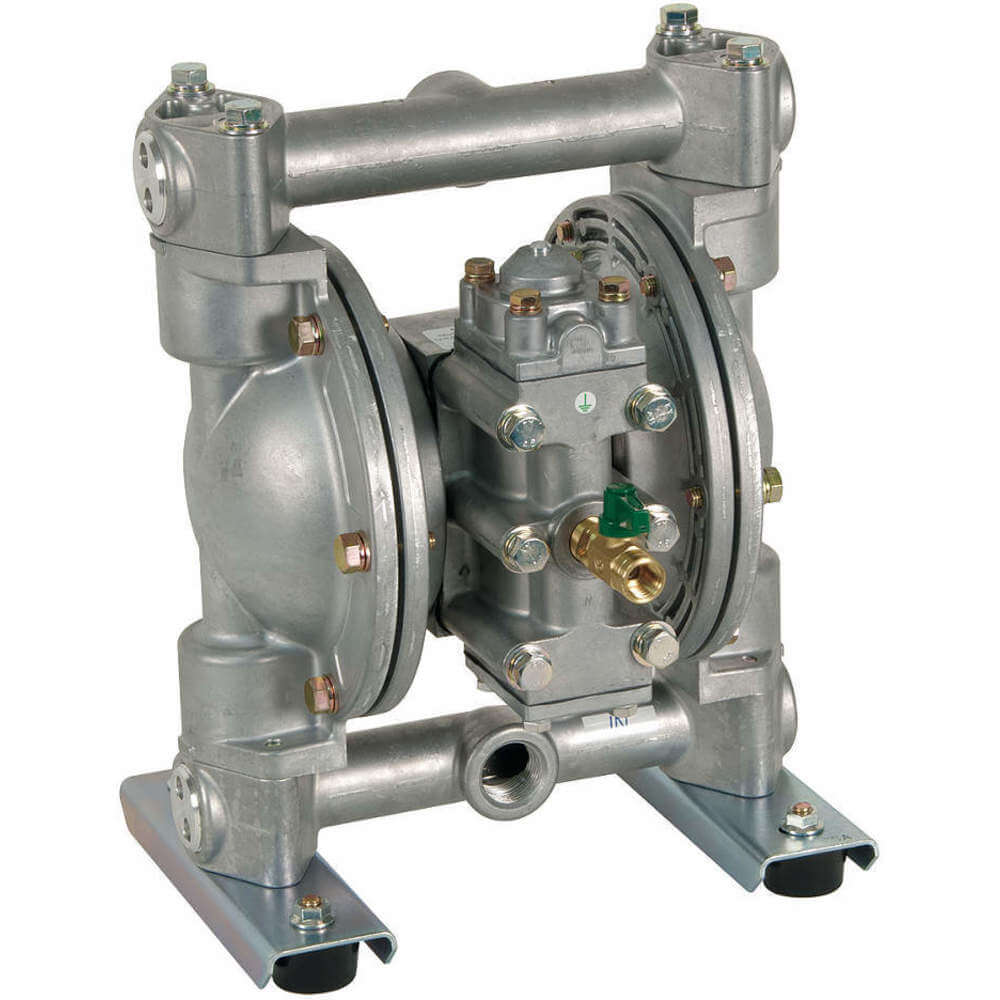

Dayton 6PY48 diaphragm pump is designed to transfer liquids in wet pumping applications. It utilises compressed air to allow the pumping of a wide variety of liquids such as acids, caustics, solvents, paints, inks, adhesives, abrasives and slurries.

Features:

- It features two flexible Santoprene diaphragms that reciprocate back & forth to create a temporary chamber which permits both drawing in and expelling fluid through the pump.

- It comes with an EPDM seal (placed between the wetted parts) to create a leak-proof environment and protect the pump from corrosive elements.

- This pump is integrated with a ball valve that ensures that the liquid is transferred in the right direction. It prevents the liquid to flow backwards, thus protecting against damage to the critical parts of the pump.

- It is self-priming, portable and intrinsically safe. It does not overheat during continuous operation and can deliver a variable flow rate to match the required operation.

Frequently Asked Questions:

Q. What is the purpose of a diaphragm?

A. A diaphragm creates a hermetic seal between the drive mechanism and the compression chamber, allowing the pump to transfer, compress & evacuate the medium without using a lubricant.

Q. Does this diaphragm pump need lubrication?

A. No, Dayton diaphragm pump can run dry without using oil or other lubricants. This means that it will not stall or get clogged due to lack of lubrication.

Q. What does deadhead mean in a diaphragm pump?

A. Deadhead takes place when a diaphragm pump operates with no flow due to a closed or blocked discharge valve. In such cases, the pump recirculates the same water, causing the water temperature to rise and shut off to prevent damage to internal components.

Change Country

Change Country