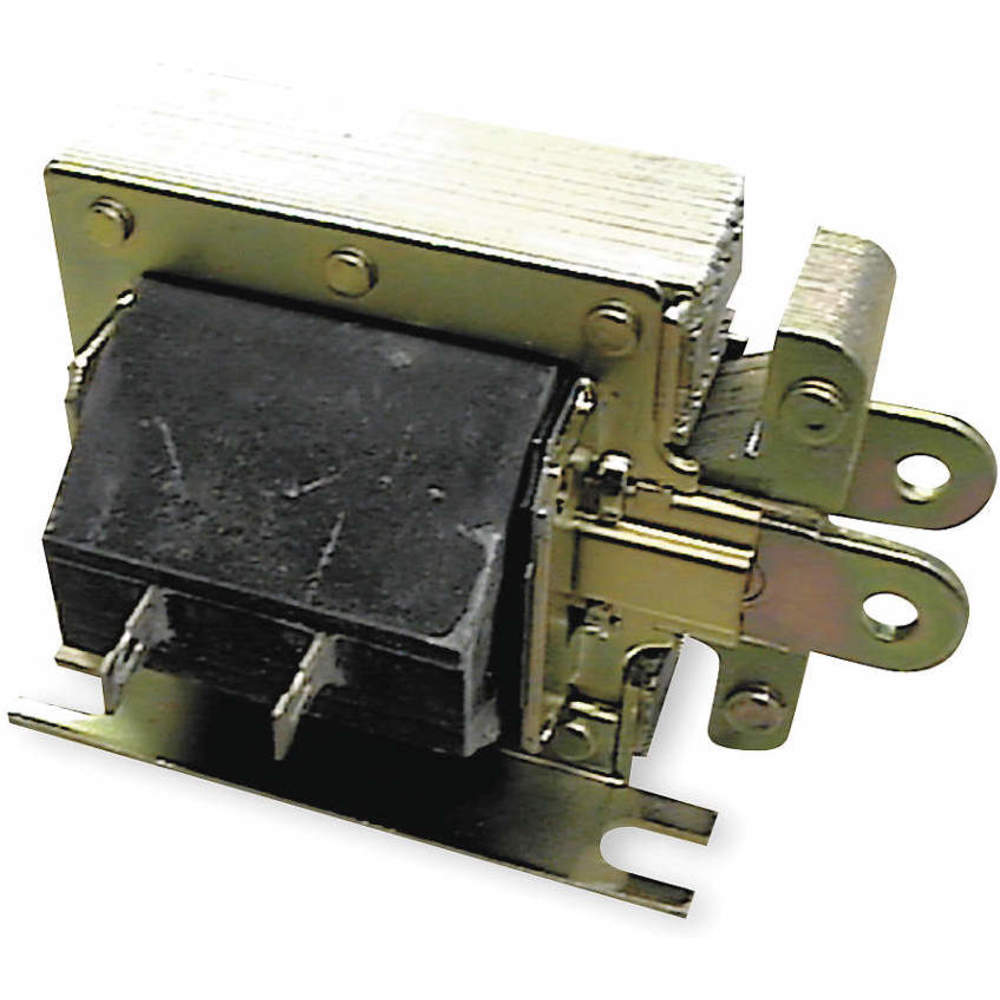

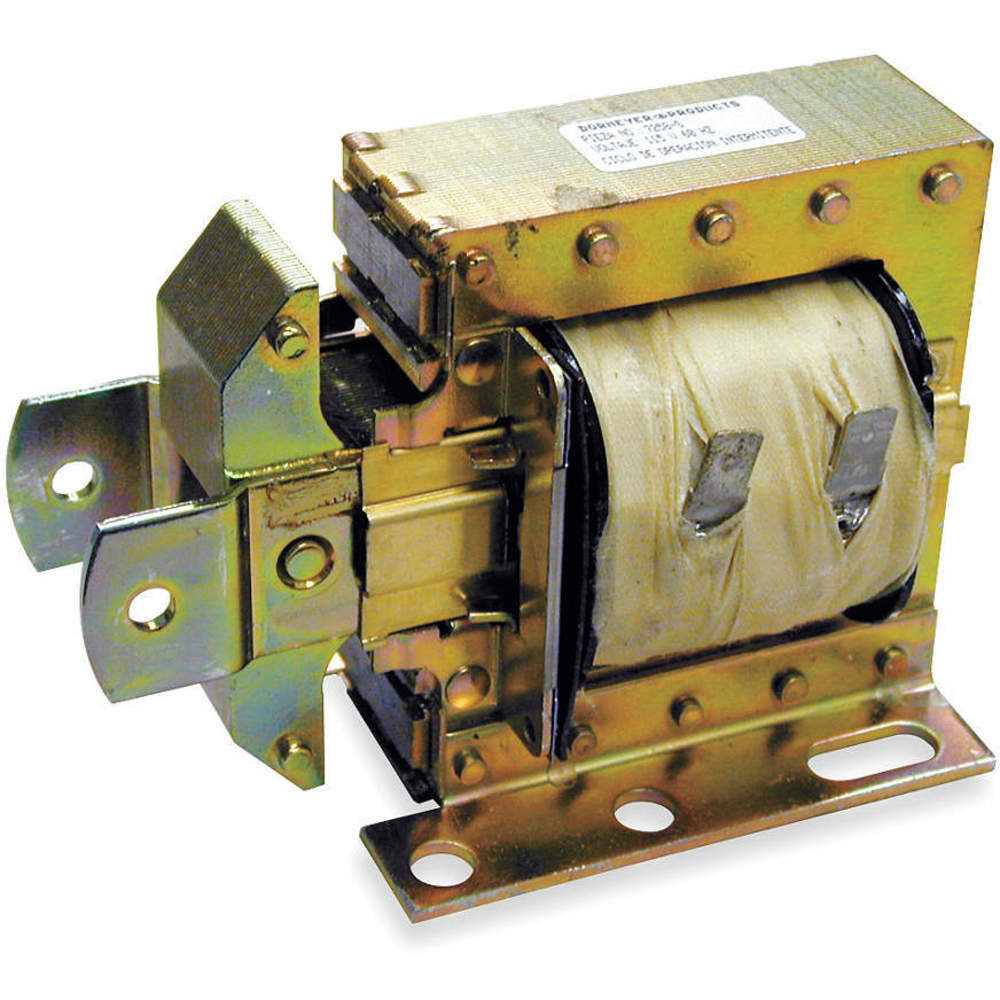

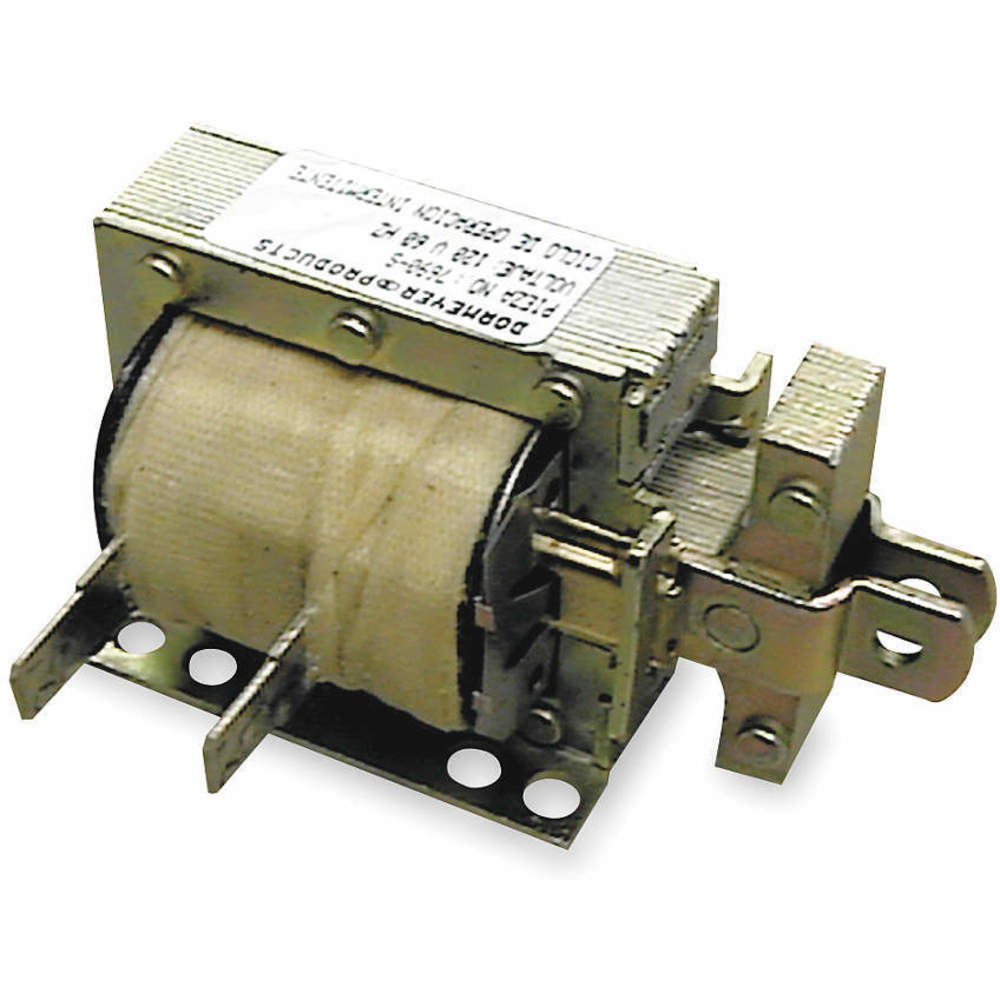

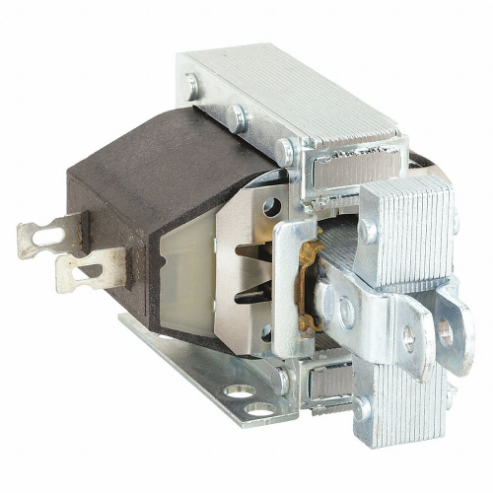

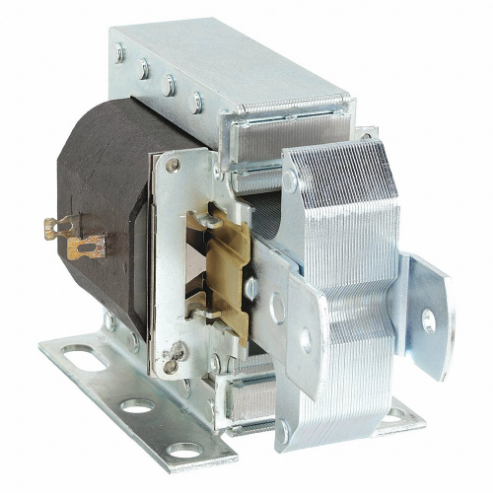

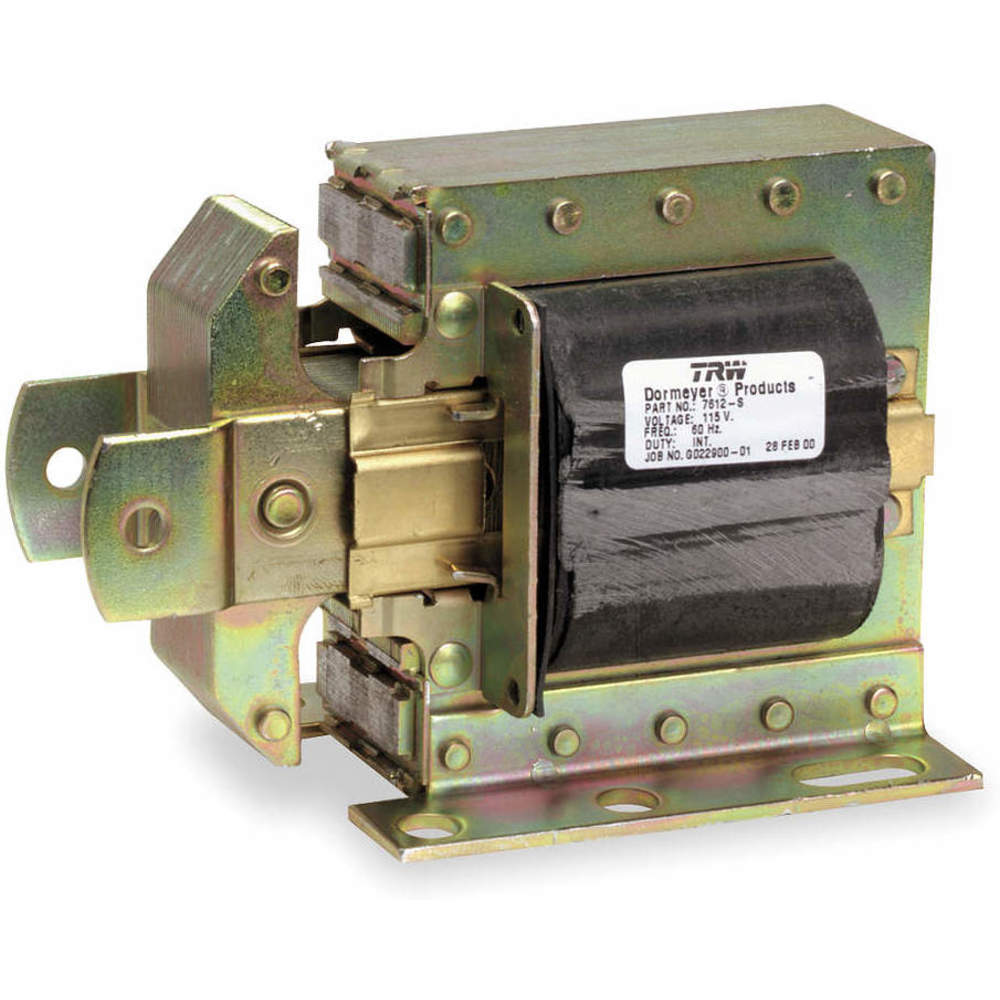

Dormeyer 2005-M-1 laminated solenoid is a wounded long piece of wire shaped in a coil. It is used to slow the flow of electricity in a circuit and is suitable to convert the electrical energy into linear motion in medical equipment, vehicles, locks, printers & industrial equipment.

Working Mechanism:

- It works on the principle of electromagnetism.

- With the use of a metal core, the solenoid creates the magnetic field while producing linear motion from electric current.

- Placing a metal core inside the coil causes the magnetic lines of flux to be concentrated on the core when the coil's magnetic field is formed, increasing the coil's induction compared to an air core.

Features:

- Dormeyer 2005-M-1 solenoid comes laminated with durable steel to reduce the stray current and offers a corrosion-resistant plunger & frame.

- It has encapsulated or taped coils, polyester or nylon bobbins, brass plunger guides and steel plunger springs for maximum efficiency.

- This Class A unit allows a pull-type continuous duty cycle with a long stroke to ensure efficient performance.

- It is equipped with solder lug coil terminals for strong durable joints and mounting holes to ensure quick installation.

Standards and Approvals:

Frequently Asked Questions:

Q. What are the types of solenoids?

A.

- AC laminated

- DC- C frame laminated

- DC- D frame laminated

- Linear solenoid

- Rotary solenoid

Q. What is stroke in solenoid?

A. The solenoid stroke measures how far the armature travels from its initial position to its final position.

Q. What is the pull force range of these 2005-M-1 solenoids?

A. These Dormeyer products 2005-M-1 solenoids have a pull force ranging between 64.0 to 128.0 oz.

Change Country

Change Country