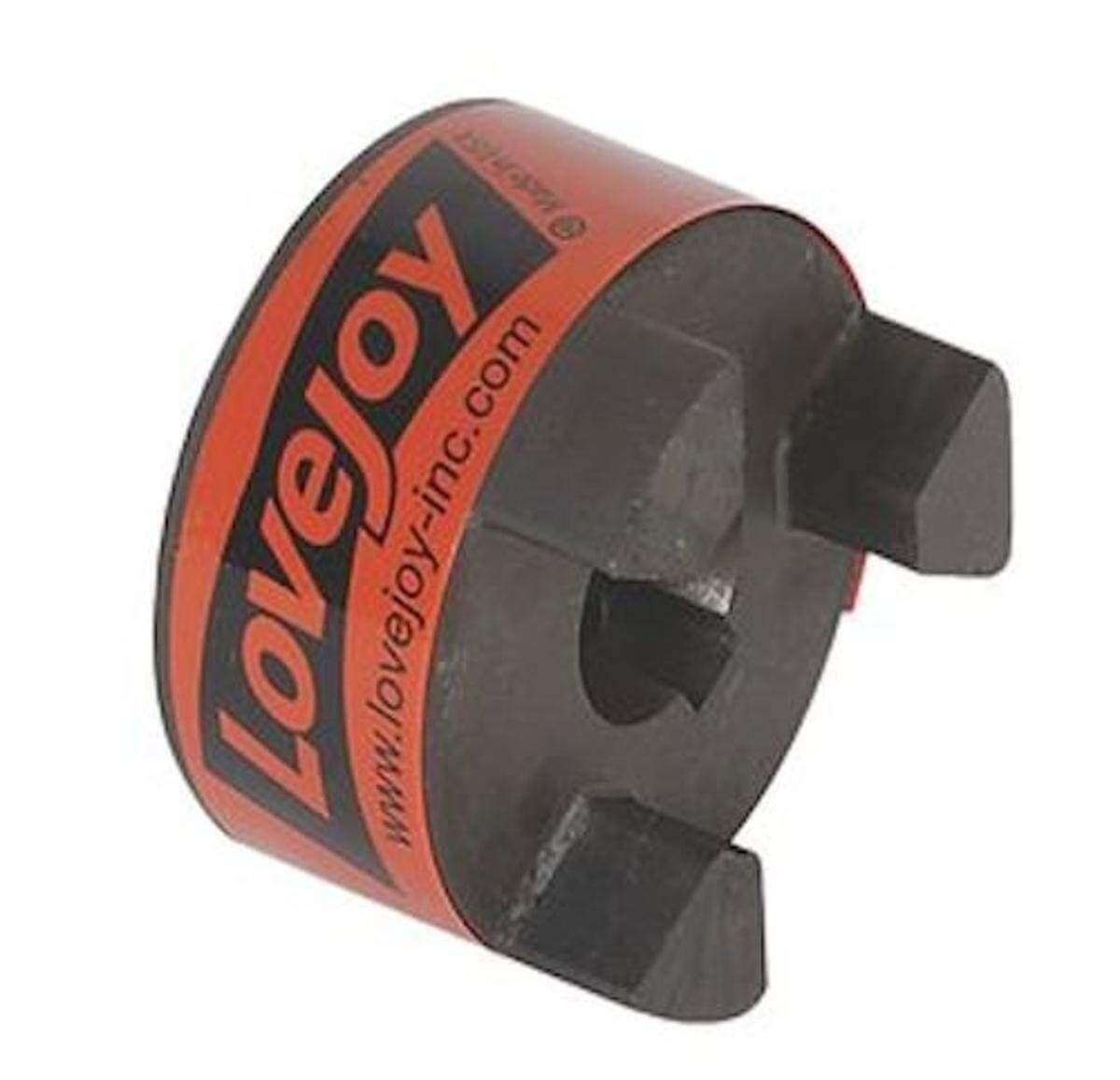

Lovejoy 68514410688 jaw coupling hub is ideal for connecting two shafts in mechanical power transmission systems, ensuring efficient torque transfer while accommodating misalignment and vibration. This coupling hub is used in pumps, compressors and conveyors.

Features:

- This hub features sintered iron / cast iron construction, offering resistance to oil, dirt, sand, moisture & grease and providing durability and versatility.

- It has the capacity to effectively accommodate both angular and parallel shaft misalignment, providing flexibility in various applications.

- This hub offers a shaft-to-shaft connection, making it ideal for general industrial-duty applications.

Frequently Asked Questions:

Q. What are the factors to consider while choosing this Lovejoy jaw coupling hub?

A. Major factors include coupling size, bore size, material, misalignment tolerance, torque rating, environmental conditions, ease of installation, compatibility and application requirements.

Q. How do I install this Lovejoy jaw coupling hub?

A.

- Ensure safety measures are in place, including powering off and locking out the machinery before starting installation.

- Prepare the shaft ends by cleaning and inspecting them for smoothness.

- Inspect the coupling hub for any visible defects or damage prior to installation.

- Properly align the shafts to minimise angular and parallel misalignment.

- Slide the coupling hub onto one shaft, ensuring it seats against the shaft shoulder.

- Secure the hub to the shaft using appropriate fasteners and follow manufacturer torque specifications.

- Slide the second shaft through the other end of the hub, ensuring proper alignment.

- Secure the second shaft in place with suitable fasteners.

- Double-check the torque on all fasteners to ensure they are tightened correctly.

Q. What safety precautions should I take while using this jaw coupling hub?

A.

- Follow proper lockout / tagout procedures to de-energise machinery before starting work.

- Wear necessary personal protective equipment (PPE) like safety glasses and gloves.

- Ensure that personnel involved are trained and qualified for the task.

- Use proper lifting techniques and equipment when handling heavy components.

- Keep the work area clean, organised and free of tripping hazards.

- Inspect the coupling hub and components for defects, damage or wear before installation.

- Properly align shafts to minimise misalignment and prevent premature wear.

- Tighten fasteners to the manufacturer's specified torque values for a secure connection.

- Ensure safety guards and covers on machinery are in place and functioning correctly.

- Know the location and use of emergency stop buttons in case of an emergency.

- Disconnect and isolate electrical power sources when working near electrical components.

- Be aware of rotating or moving parts, keeping loose clothing, jewellery and body parts away from them.

- Regularly inspect the coupling hub during routine maintenance checks for wear, damage or loose fasteners.

- Use the correct tools and equipment for the job to prevent accidents or component damage.

Change Country

Change Country