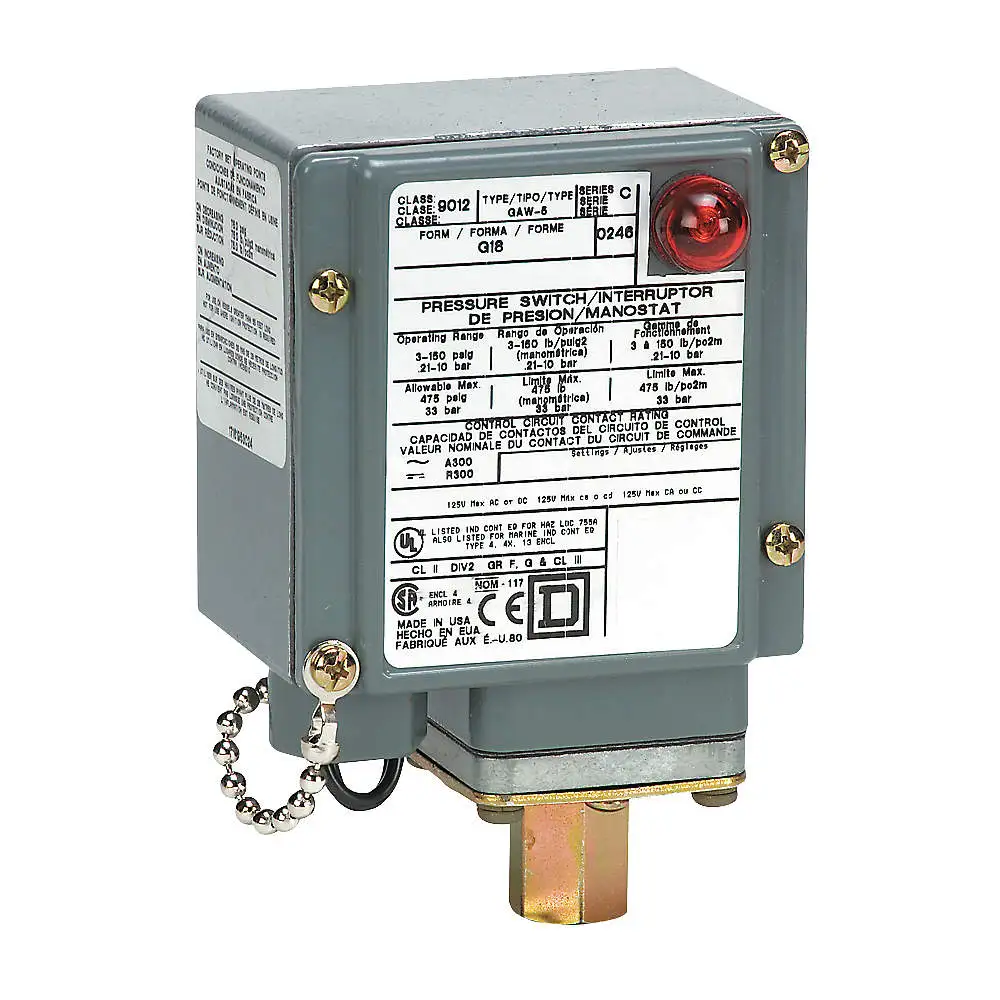

Square D 9013FSG2J24 pressure switch is used in water supply & distribution plants and the HVAC, agriculture and oil & gas industries for pressure sensing & controlling compressors, moulding presses, injection moulders and jet, submersible & reciprocating pumps.

Working Mechanism:

- Mount the pressure switch securely in a suitable location.

- Disconnect power to the device you are controlling.

- Connect the inlet port to the water supply and the outlet port to your device.

- Locate the adjustment screw on top of the pressure switch.

- Turn the screw clockwise to increase the cut-in pressure.

- Adjust the screw to set the desired cut-in pressure.

- Set the cut-out pressure by adjusting the screw.

- If available, adjust the pressure differential to prevent rapid cycling.

- Reconnect the power to your device.

- Slowly open the water supply valve to observe the switch in action.

- Fine-tune pressure settings for optimal device operation.

Features:

- Square D 9013FSG2J24 pressure switch features screw clamp terminals for improved electrical connections and a 0.25-inch NPSF internal thread for enhanced fluid connections.

- This Schneider Electric switch is equipped with a diaphragm actuator that can be operated from any position.

- It comes with an adjustable differential scale to regulate the internal settings.

- This Pumptrol switch features a polypropylene enclosure for enhanced resistance to corrosive environments.

- It offers an electromechanical design to monitor and control pressure conditions for both industrial and end-user applications.

- This pressure switch can withstand power up to 3 horsepower at 240V in 3-phase configurations.

Frequently Asked Questions:

Q. How do I clean and maintain Square D 9013FSG2J24 pressure switch?

A.

- Power off the connected device to the pressure switch.

- Wear appropriate personal protective equipment (PPE).

- Inspect the pressure switch regularly for dirt, debris, or corrosion.

- Clean the exterior using a soft, dry cloth or brush.

- For thorough cleaning, dampen a cloth with mild soap and water, and wipe gently.

- Check pressure ports for blockages and use compressed air or a brush to clean.

- Inspect and clean exposed contacts using a brush or compressed air.

- Check seals and gaskets for wear or damage; replace if needed.

Q. How do I choose a pressure switch for my applications?

A.

- Define the pressure switch's role in your system.

- Identify required pressure levels.

- Ensure compatibility with fluid.

- Match voltage and current requirements.

- Consider operating conditions.

- Choose adjustable or fixed settings.

- Select suitable contact configuration.

Q. What safety precautions should I take while using this pressure switch?

A.

- Always disconnect power before handling or servicing the pressure switch.

- Allow only trained individuals to install, adjust or maintain the switch.

- Use the pressure switch within its specified temperature and humidity range.

- Ensure proper ventilation to prevent overheating of the switch.

- Verify that the pressure switch is suitable for the specific fluid or gas it will be exposed to.

- Do not exceed the maximum pressure ratings of the switch to prevent damage.

- Follow proper electrical wiring practices to avoid shocks or short circuits.

- Maintain the integrity of seals and gaskets to prevent leaks.

- Periodically check for wear, corrosion or damage and address issues promptly.

Change Country

Change Country