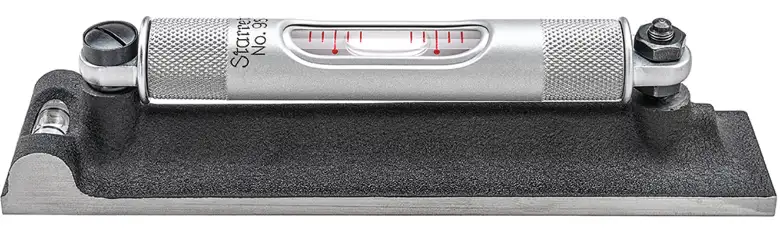

Starrett 98-4 precision machinist level is designed to ensure accuracy in levelling and measurement tasks within various industrial and machining operations. It is used in metalworking, woodworking and construction applications.

Working Mechanism:

- Place the machinist level on the surface to be measured.

- Utilise the stable cast iron base with a full-length involute groove to prevent shifting.

- Open the friction-fit closing cover of the satin-finished brass tube housing the vial.

- Observe the bubble's position within the glass vial to gauge angular deviations.

- If needed, calibrate the vial to a positive setting by aligning the bubble with a reference marking.

- Record angle measurements based on the bubble's position relative to graduated markings.

Features:

- This precision level features cast iron base construction to provide stability and rigidity for reliable measurements.

- It offers the flexibility of being adjustable to a positive setting, allowing users to calibrate the level to a specific reference angle for customised measurements.

- This machinist level has ground and graduated vials, enabling precise measurement of angular deviations.

- It features a friction-fit closing cover for protection and aesthetic appeal and a base that boasts a reliable full-length involute groove for stable placement and accurate readings.

- This precision level has a vial made from glass, ensuring clarity & accuracy in measuring angular deviations.

Frequently Asked Questions:

Q. How does the adjustable positive setting work?

A. The adjustable positive setting lets you calibrate the vial to a specific reference angle. This customisation aids in achieving accurate measurements based on your needs.

Q. How do I read the measurements on the graduated vial?

A. The bubble's position relative to the graduated markings indicates the angular deviation. Aligning the bubble with a specific marking provides the measurement.

Q. What are the factors to consider while choosing a precision machinist level?

A. Major factors include the required measurement accuracy, the specific angles of measurement needed, the level of durability required for the intended environment and the availability of adjustable positive settings for calibration.

Change Country

Change Country