Uniweld 71 torch handle is ideal for welding metallic workpieces using oxygen & fuel gasses / acetylene. It has a front valve design for connecting the oxygen & fuel supply hoses to the torch. This Uniweld torch model 71 is suitable for construction, fabrication and maintenance & repair applications in shipyards, railroads, farms and automobile shops.

Working Mechanism:

- After attaching the handle to the hose lines & gas cylinders through a flow / pressure regulator, connect the welding nozzle to the torch handle.

- Control the fuel & oxygen pressure to the torch handle using their respective regulators.

- Open the fuel & oxygen knobs on the torch handle and bring the assembly near the metal pieces to be welded.

- Use a striker to start a fire and adjust the flame using the knobs on the handle.

- Bring the assembly near the metal pieces that are clamped together and start heating them at the joining edges.

- After some time, the heated edge would start melting and then will join together to form a single welded metal piece.

- Close the valves on the cylinders & the torch handle. Purge the hoses of any leftover gas.

- Sand the welded piece for smooth edges / surface.

Features:

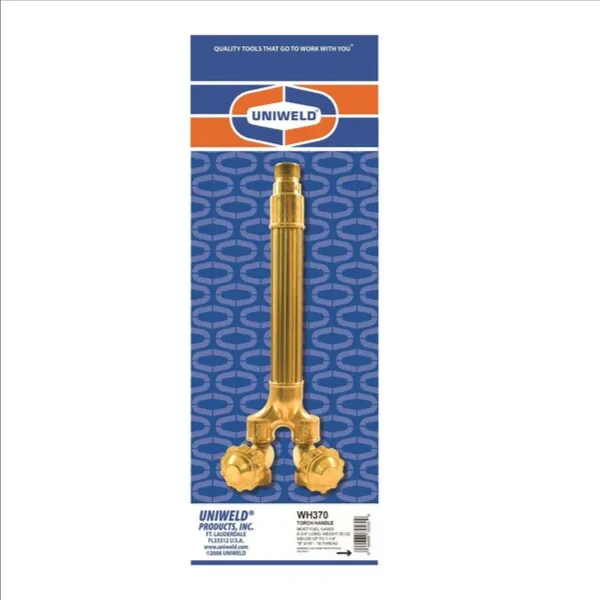

- Uniweld 71 torch handle has a tube within a tube design (two silver brazed tubes contained inside this vented brass handle).

- It has a ribbed brass front of 6-inch length and a forged brass rear torch & valve body.

- This Uniweld model 71 handle features stainless steel ball point valves with Teflon packing for long operating life.

- It also has four O-ring seals for leak-proof operation, quick maintenance & safety.

Compatible Accessories:

- Fuel Hoses: Two fuel hoses carrying oxygen & fuel from gas cylinders are connected to this welding torch.

- Strikers Or Lighters: These strikers or lighters are used to start the flame in the welding nozzle. Users should choose a striker that can be fired from a distance to protect their hands from injuries.

Standards and Approvals:

Frequently Asked Questions:

Q. What are some common safety points to follow while operating this Uniweld 71 torch handle?

A.

- Check torch handle and other attachments for clogged debris or metal particles.

- Check for any cracks or breaks on the handle to prevent fuel or oxygen leaks.

- Check that the attached valves, hoses & pressure gauges are delivering the correct pressure from the cylinder into the torch lines.

- Make sure that the welding nozzles & other attachments are tightly secured on the torch handle.

Q. What is the welding capacity of this Uniweld 71 torch handle?

A. Uniweld model 71 torch has a maximum welding thickness of 1/4 inches.

Q. How are hoses connected to this Uniweld 71 torch handle?

A. Uniweld torch model 71 has 3/8 inch-24 UNF connections for easy attachment to oxygen / fuel hoses.

Change Country

Change Country