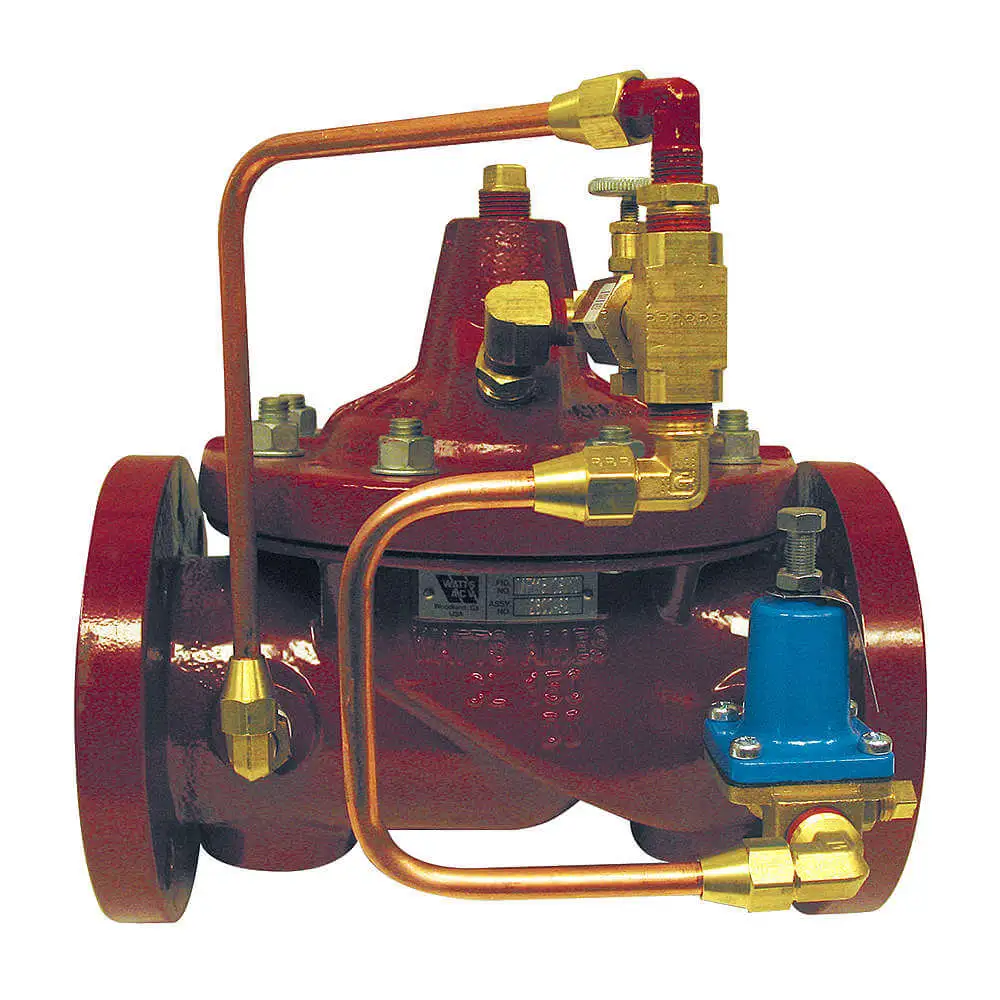

Watts 115-3 FL pressure reducing valve reduces the incoming water pressure to a manageable level for industrial and commercial plumbing systems. It automatically adjusts the flow of water based on the incoming pressure.

Features:

- It features a ductile iron (ASTM A536) body for structural rigidity and durability.

- This reducing valve has Buna N seals, ensuring leak-free operation and reliability.

- It is coated with a 3-part ArmorTek epoxy for corrosion resistance and reduced maintenance.

- This reducing valve allows an intermittent flow rate of 570 gpm for peak demand situations.

Compatible Accessories:

- Watts 100RK-2-1-2 Valve Rebuild Kit: It is ideal for overhauling or refurbishing a valve to ensure proper functionality. This kit replaces worn-out or damaged components within a valve assembly.

Frequently Asked Questions:

Q. How to install Watts 115-3 FL pressure reducing valve?

A.

- Measure water pressure with a gauge.

- Gather tools such as valves, gauges, fittings, tape, soldering supplies, pliers, wrench, cutter and torch.

- Use threaded fittings to attach gauges on each side of the valve for monitoring.

- Mark and cut the water pipe where the valve will be installed using a tubing cutter.

- Apply flux and solder the valve to the pipe after removing gauges and O-rings.

- Reinstall pressure gauges after cooling, reattach gauges and O-rings.

Q. What safety precautions should I take when using this pressure-reducing valve?

A.

- Ensure upright valve installation in equipment or pipes. Horizontal placement is acceptable for liquid pipes prone to thermal expansion.

- Place the valve in easily accessible spots for maintenance. Ensure sufficient workspace around it.

- Prevent resistance at the valve outlet to avoid pressure buildup. Install it as close as possible to protected equipment or pipes.

- Prioritise testing and checking tightness before installation. Regular maintenance during use ensures proper functioning.

Q. How do I select the right pressure reducing control valve for my application?

A. Selecting the right pressure reducing control valve involves considering factors such as the fluid type, flow rate, operating pressure range, temperature, pipe size and system requirements.

Change Country

Change Country