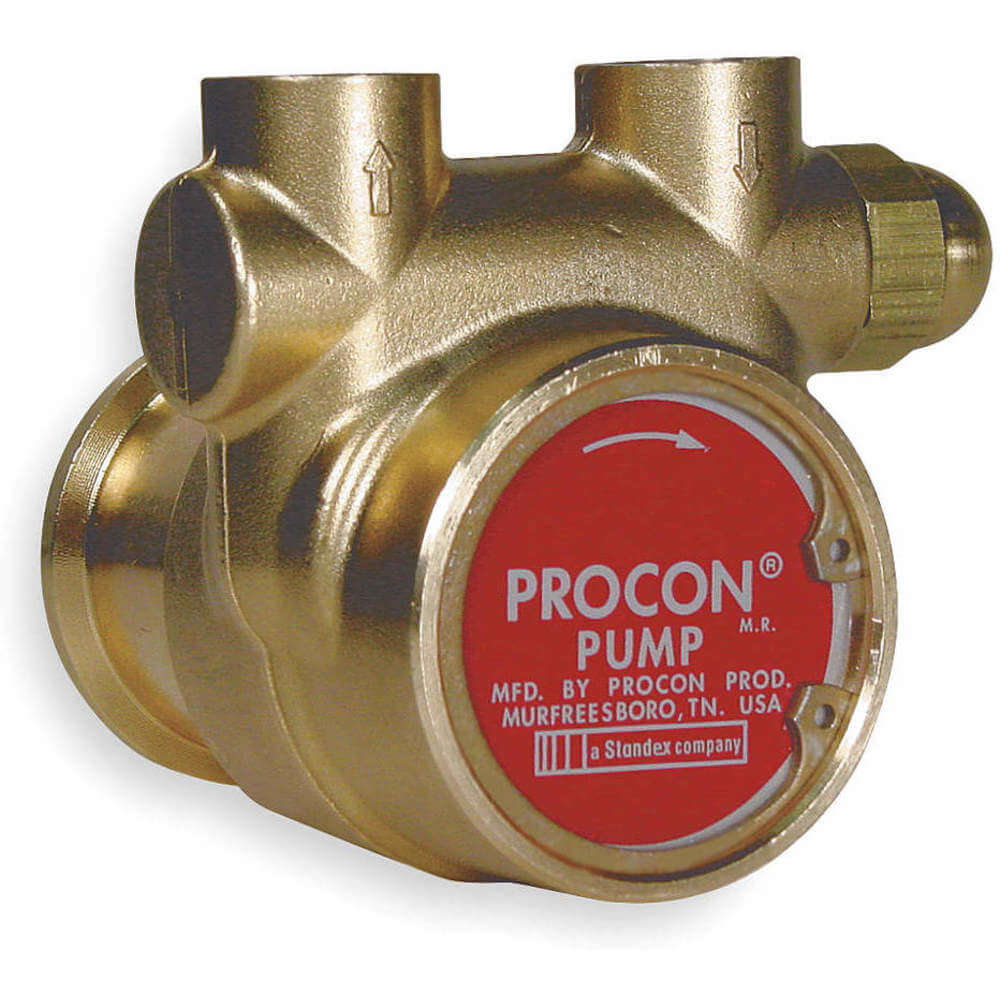

Procon 102A100F11PA rotary vane pump utilises a positive displacement mechanism with a rotor containing vanes or blades inside a cylindrical housing. It is used in beverage dispensing systems, coffee machines, water purification systems, cooling equipment & fluid transfer processes in industrial settings.

Working Mechanism:

- A rotary vane pump operates by rotating a rotor inside a cylindrical casing.

- As the rotor spins, vanes are pushed outward, creating a vacuum and drawing fluid or gas from the inlet into the expanding space.

- The vanes then move inward, compressing the fluid or gas, which is subsequently forced out through the outlet.

- This continuous suction, compression and discharge enable the pump to maintain a steady flow of fluids or gases.

Features:

- This rotary vane pump features brass construction for corrosion resistance and durability.

- It features 3/8 inches port hole size of NPT for easy connection to compatible fittings and pipelines.

- This pump offers clamp-on mounting for secure & convenient installation.

- It features EPDM / nitrile elastomer seals for leakproof operation.

- This pump further features a double flat drive configuration for ensuring efficient & reliable power transmission.

- It has a flow rate of 100 GPH, making it suitable for applications requiring a consistent & moderate flow of fluid.

- It offers a solid-brass valve to provide robust & dependable performance.

Compatible Accessories:

- Procon 1113 V-band clamp: It provides a secure connection between cylindrical components, offering a reliable & tight seal for various applications.

Frequently Asked Questions:

Q. What is the recommended fluid operating temperature for the rotary vane pump?

A. This pump has recommended fluid operating temperatures ranging from -4 to 160 degrees F.

Q. What safety precautions should I take while operating a rotary vane pump?

A.

- Ensure proper grounding to prevent electrical hazards.

- Operate the pump in a well-ventilated area with adequate space for airflow & heat dissipation.

- Regularly inspect the pump for leaks and address them promptly.

- Wear appropriate personal protective equipment when handling hazardous fluids or gases.

- Avoid overloading the pump to prevent overheating and damage.

- Never run the pump without adequate lubrication & fluid.

- Secure all connections, hoses and fittings to prevent leaks during operation.

- Avoid smoking or open flames near the pump, especially with flammable materials.

Q. What is the maximum noise level of this rotary vane pump?

A. The maximum noise level produced by a rotary vane pump is 60 dBA.

Change Country

Change Country