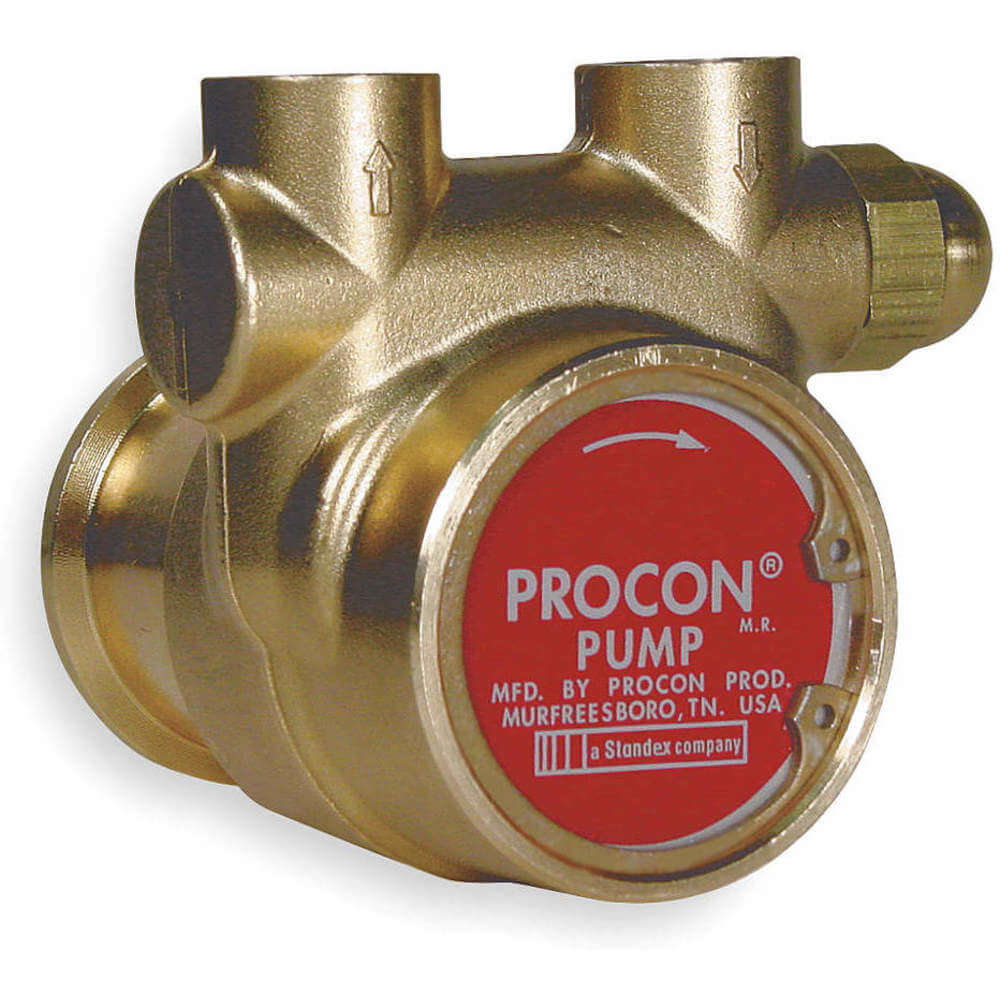

Procon 112A035F11CA rotary vane pump is a fluid transfer unit used in water treatment, food and beverage and coffee machines for pumping water, beverages and other liquids. The pump's compact design and compatibility with standard plumbing setups make it efficient and effective for fluid transfer.

Working Mechanism:

- This pump features a casing that houses a central rotor with vanes, which move eccentrically.

- As the rotor rotates, the vanes move outward, creating a seal.

- By the rotation of the vanes, the pump draws fluid or gas into a sealed chamber.

- As a result, the sealed chamber's volume decreases, compressing the trapped fluid or gas.

- Through the outlet port, the pump expels the compressed fluid or gas.

- The rotor continues to rotate continuously, sustaining the process of suction, compression and discharge.

Features:

- This pump has brass housing material that offers increased durability and reliability.

- It offers 3/8 inch NPT inlet and outlet connections, providing compatibility with standard plumbing setups.

- This pump is equipped with EPDM / nitrile elastomers, ensuring compatibility with fluids and preventing leaks or damages.

- It has a flow rate of 35 GPH, allowing for efficient and effective fluid transfer.

- This pump is designed to operate in fluid temperatures ranging from -4 to 160 degrees F for diverse environmental conditions.

- It offers a maximum mechanical horsepower requirement of 0.29 hp, ensuring energy efficiency and cost-effectiveness during use.

- This pump is integrated with an internal relief valve for safeguarding the system and preventing overpressure situations.

Frequently Asked Questions:

Q. How do I inspect a leakage in this pump?

A.

- Check for visible leaks, stains or wetness around the pump.

- Listen for hissing or sucking sounds that may indicate leaks.

- Feel for wet areas around connections and fittings.

- Look for cracks or wear and replace seals and gaskets if needed.

- Ensure that all fittings are properly tightened.

- Test the pump under operating conditions to identify leaks.

- Check for sudden drops in fluid levels.

- Look for leaks or clogs in the drain lines.

- Inspect for damage or excessive wear on the rotor and vanes.

- Apply leak detection solutions to find hidden leaks.

- Verify the proper function of the relief valve to avoid leaks.

- Watch for decreased efficiency, which may signal leakage.

Q. What safety precautions should I take while using this Procon 112A035F11CA rotary vane pump?

A.

- Read the user manual thoroughly before operating the pump.

- Ensure that the pump is placed on a stable and level surface.

- Check for signs of damage or wear and replace any faulty parts.

- Use appropriate personal protective equipment (PPE) like gloves and safety glasses.

- Verify pump compatibility with the fluid and provide proper lubrication if needed.

- Connect the pump to a suitable power source following voltage and power requirements.

- Regularly inspect and clean the pump to maintain efficiency and prevent hazards.

- If malfunctioning or unusual noises occur, stop using the pump and seek professional assistance.

- Store the pump in a dry and secure location, away from extreme temperatures and hazards.

- Follow all safety guidelines and warnings from the manufacturer for safe operation.

Q. Which type of drive is used in this pump?

A. A 0.118-inch double flat drive is used in this Procon 112A035F11CA rotary vane pump for improved performance during high-speed operations.

Change Country

Change Country